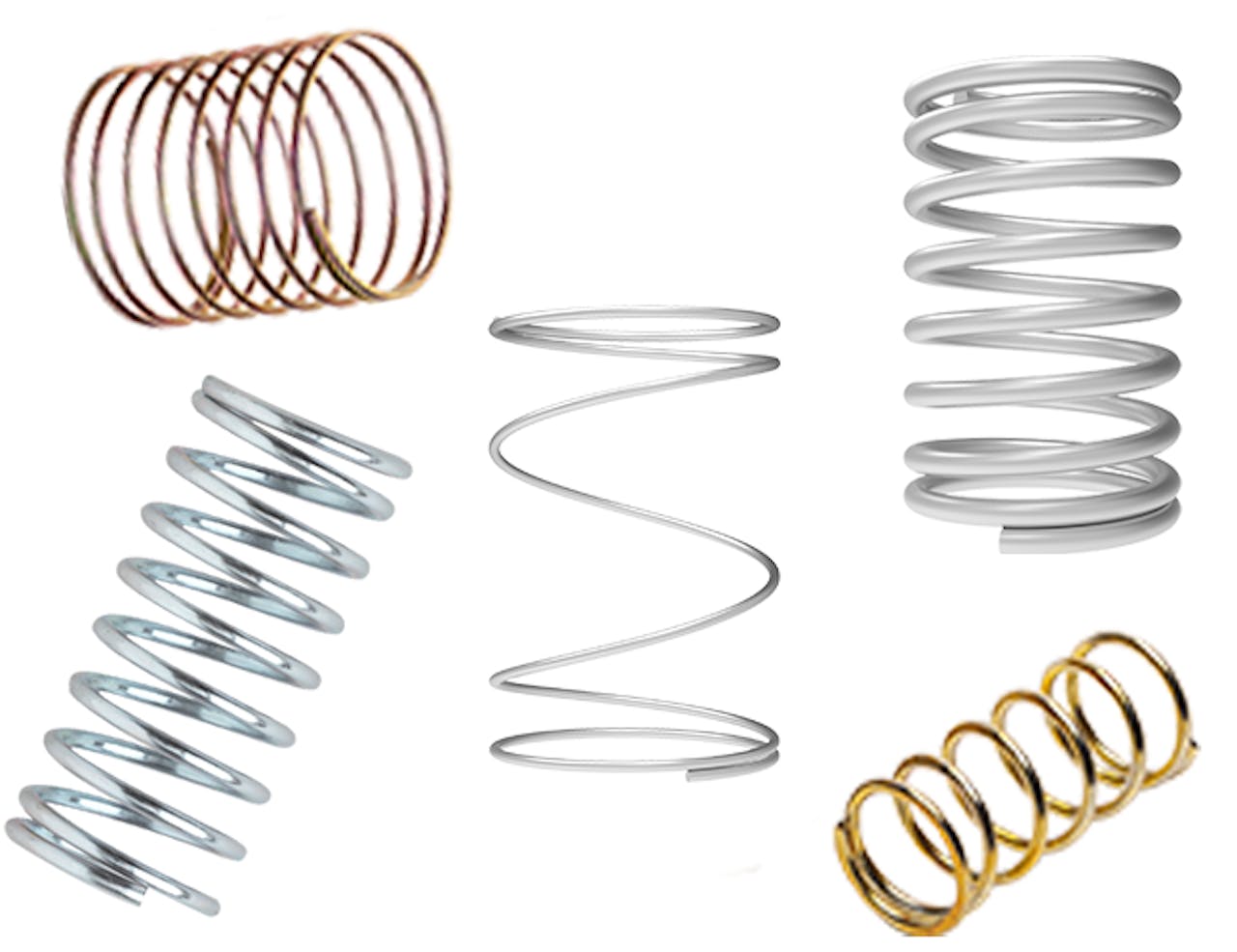

Custom Spring Products

We manufacture custom, made-to-print springs and wire forms. With minimums of just 10 pieces and the ability to support full production runs, we can make everything from coiled springs to flat springs for nearly any application.

Compression Springs

Our capabilities range from approximately 0.006" to approximately 0.625" wire diameter. Compression springs are open coiled helical springs that resist a compressive force applied axially. The shape may be cylindrical, conical, tapered, convex (hourglass), concave (barrel) or a combination of these. See the link for some pre-engineered compression spring designs.

Altering the spring's ends, direction of the helix, material type and finish, allows a compression springs to meet a variety of specially designed spring needs. Die springs are ideally suited for heavy load spring applications that have a limited operating range.

Extension Springs

Our capabilities for extension springs range from 0.008" to over 0.375". Helical extension springs store energy and exerts a pulling force. The initial tension will determine how tightly wound the spring is coiled. Initial tension is defined as the minimum force required to begin to separate coils. This force can also be adjusted to achieve your custom load requirements. The ends of extension springs can come in different configurations. The looped ends can be machine loops, cross-over center loops, double full loops, extended hooks and side hooks/loops. See the link for some pre-engineered extension spring designs.

Torsion Springs

Our torsion spring capabilities range from 0.008" to 0.250" wire diameter. Helical Springs used to apply a torque or store rotational energy are commonly referred to as torsion springs. The two most common types are single and double-bodied springs. Torsion springs are generally mounted around a shaft or arbor and must be supported at three or more points. Various kinds of ends are available to facilitate mounting. See the link for some pre-engineered torsion spring designs.

Wire Forms

Our wireform capabilities start at 0.008" to about 0.200", but in some situations we have provided up to 0.500" wire diameter product. Industries utilize a variety of custom wire and metal forms in their products. These individual component designs can vary in material, width, thickness, strength, form, and function.

Since standard wire and metal forms do not exist, our experienced craftsmen are able to meet individual application challenges by utilizing their professional experience, flexible tooling, and production capabilities.

Your custom wire and metal form component can be readily designed and manufactured upon request. Please create a drawing or rough sketch of the part you need and e-mail us at quotes@foxvalleyspring.com.

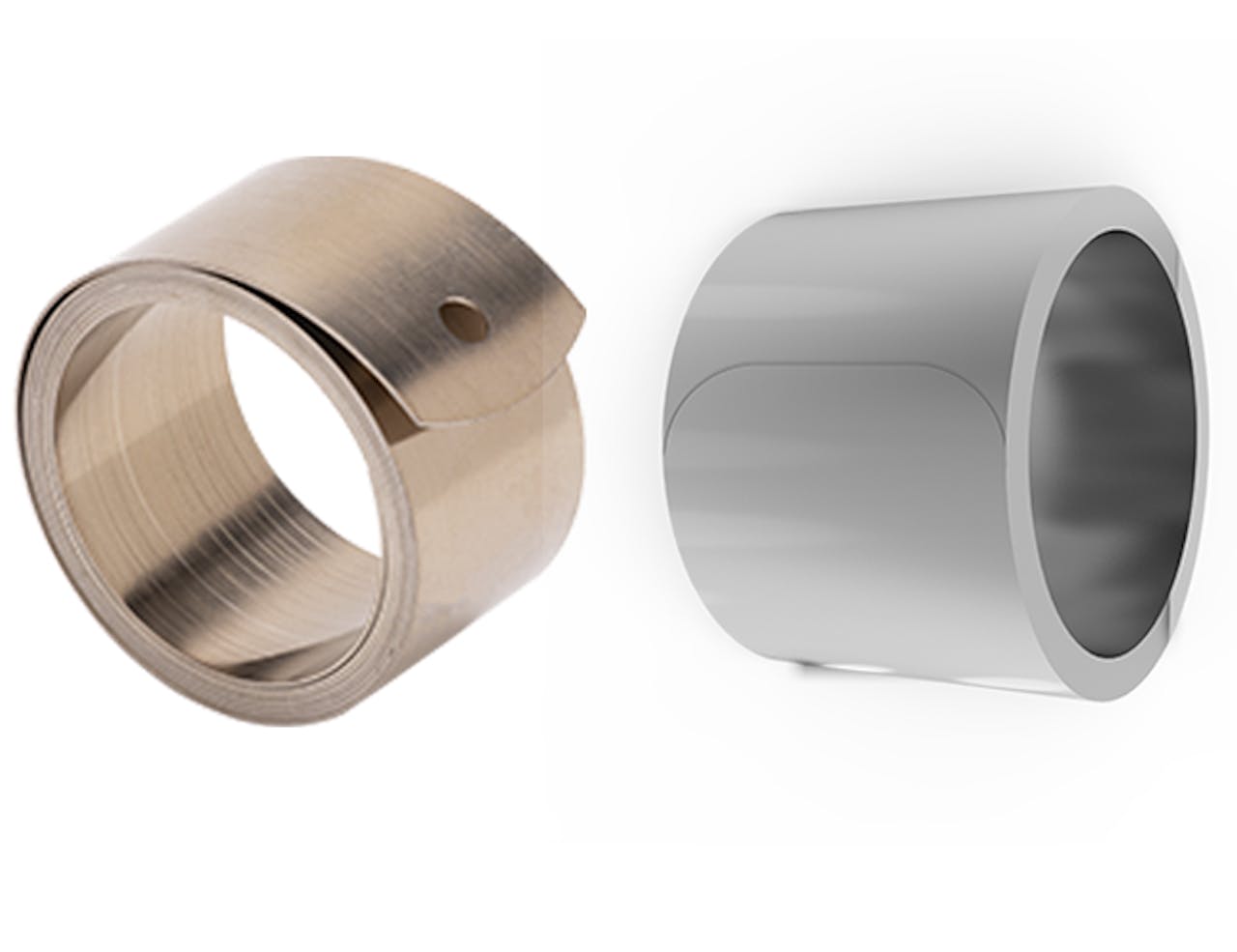

Constant Force Springs & Power Springs

Constant force or power springs exert a constant force over its range of motion. That is, it does not obey Hooke's law. Generally constant-force springs are constructed as a rolled ribbon of spring steel such that the spring is relaxed when it is fully rolled up.

Flat Springs

Since no standard flat steel forms exist, each design is reviewed individually. If you don't have a sample, please create a drawing or rough sketch of the part you need and e-mail it to us.

Stampings & Flat springs are typically produced from soft or hard tooling which can then be integrated within a progressive die or four slide equipment. The size of the part and anticipated volumes will dictate which process will be better suited to deliver a quality part at an economical price.

Materials, Finishes & Applications

Materials and Finishes

All of our custom products are manufactured using the highest grades of spring wire. Carbon steels include material types such as music wire, basic wire, hard drawn, oil-tempered, chrome silicon, missile wire among others. We work with a variety of stainless steel materials including 302, 316 & 17-7 PH. Fox Valley Spring also works with more exotic material types such as Hastelloy, Inconel and Monel. Material Certifications can be furnished upon request.

We partner with many local finishing companies that meet or exceed our strict quality standards. Some options we offer are zinc and powder coating in a multitude of colors, electroless nickel, E-Coat, tin, black oxide, cadmium & gold electroplating. Other surface treatments that are available include passivation, and color coding using various methods and materials to meet our customers specific needs. Processing Certifications for all processes can be furnished upon request.

Industries & Applications

Our products can be used in a wide variety of industries, including the ones below and many more.

- Energy

- Consumer Products

- Agriculture/Lawn & Garden

- Exercise/Sports Equipment

- Handicap Equipment

- Fastener Industry

- Electronics

- Fluid Handling

- Office Equipment

- Industrial Valves

- Aircraft

- Hydraulics

- Construction

- Mining & Drilling

- Food Packaging & Processing

- Medical Equipment

- Appliance

- Defense/Military

- Oil & Gas