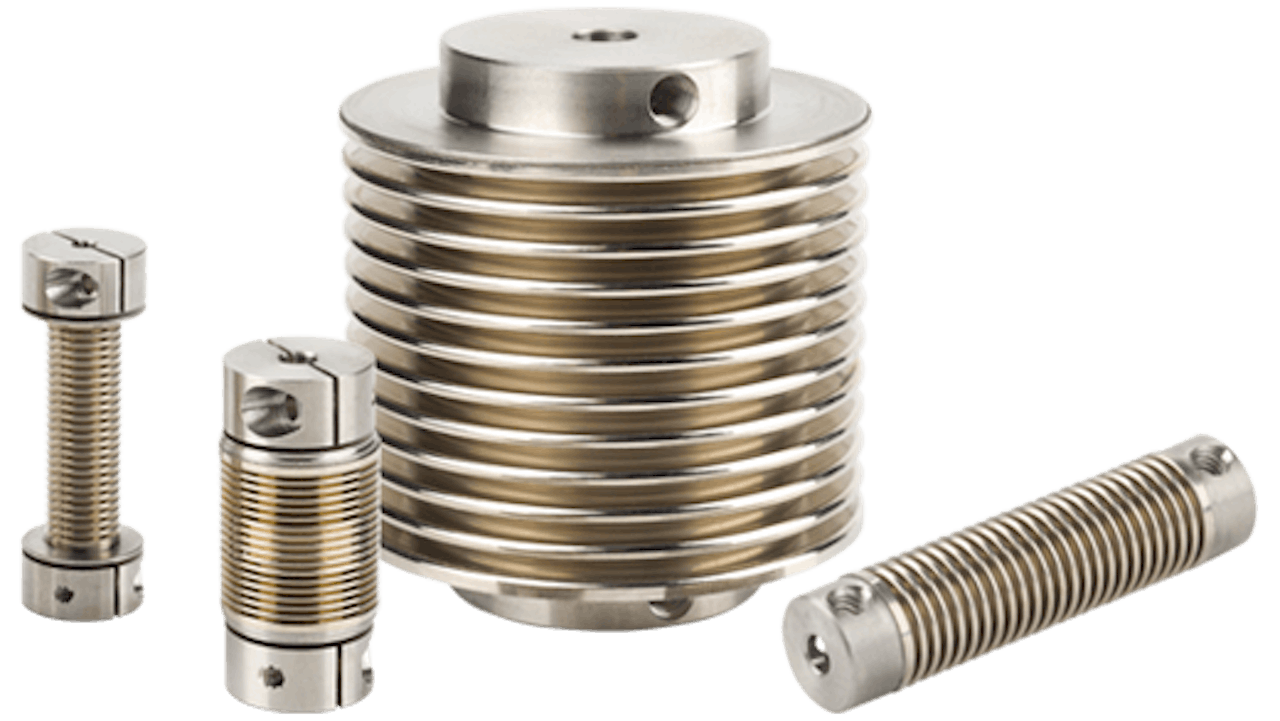

Flexible Shaft Couplings / Bellows Couplings

MW Components produces flexible shaft couplings (also called flexible couplings or flex couplings), including beam couplings (machined couplings) and bellows couplings (couplings produced with bellows convolutions) in multiple sizes and material compositions with many different attachment styles to suit your intended application. Our team of experts works with you to determine the performance requirements and coordinating specifications needed to achieve your desired outcome. We examine certain factors to determine which coupling is right for you, including torque, space limitations, RPM, and shaft misalignment.

CAD files for stock and standard flexible shaft couplings and bellows couplings are available in our online store.

CUSTOM MANUFACTURING

Custom Flexible Shaft Couplings

MW's vast machining capabilities allow us to design custom couplings, including custom machined couplings, bellows couplings, and servo couplings for various industries and applications while meeting your torque and misalignment requirements. With an unlimited variety of attachment styles including, Integral Clamp, Set Screw, Keyways, Splines, and more, you can be assured that our custom-engineered solution will suit your specialized needs and exacting specifications.

Send us your specs or configure a product.

Bellows Coupling Manufacturing & Configurations

Bellows couplings like our servo couplings (also referred to as flexible motor couplings) are typically produced using either aluminum or stainless steel using various machining services; however, specialty materials and services are also available for custom components. Multiple attachment styles are also available for added functionality. Torque range, bore ranges, operating temperatures, speed, and other performance factors will vary depending on the configuration chosen.

For more details on available coupling configurations, review the list below for a side-by-side comparison, view our Standard Coupling Comparison Guide below.

Typical Bellows Coupling Styles

| Series | End Attachment | End Type |

|---|---|---|

| SMC-300 | Adhesive | Set Screw |

| SMC-400 | Adhesive | Clamp |

| SSC-300 | Solder | Set Screw |

| SSC-400 | Solder | Clamp |

Flexible Coupling Applications

| Application | Advantages of Bellows Couplings |

|---|---|

| Encoders | Extremely low elastic windup |

| Servos | Zero backlash |

| Actuators | Zero cyclic speed variation during 360° rotation |

| Robotics | Minimal side loading |

| CNC Machine Tools | Complete customization of bellows and end pieces available |

| Other Motion Control Instruments | Lead time of 1-2 weeks on standard sizes. Contact us for stock sizes. |

Other Coupling Products

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.