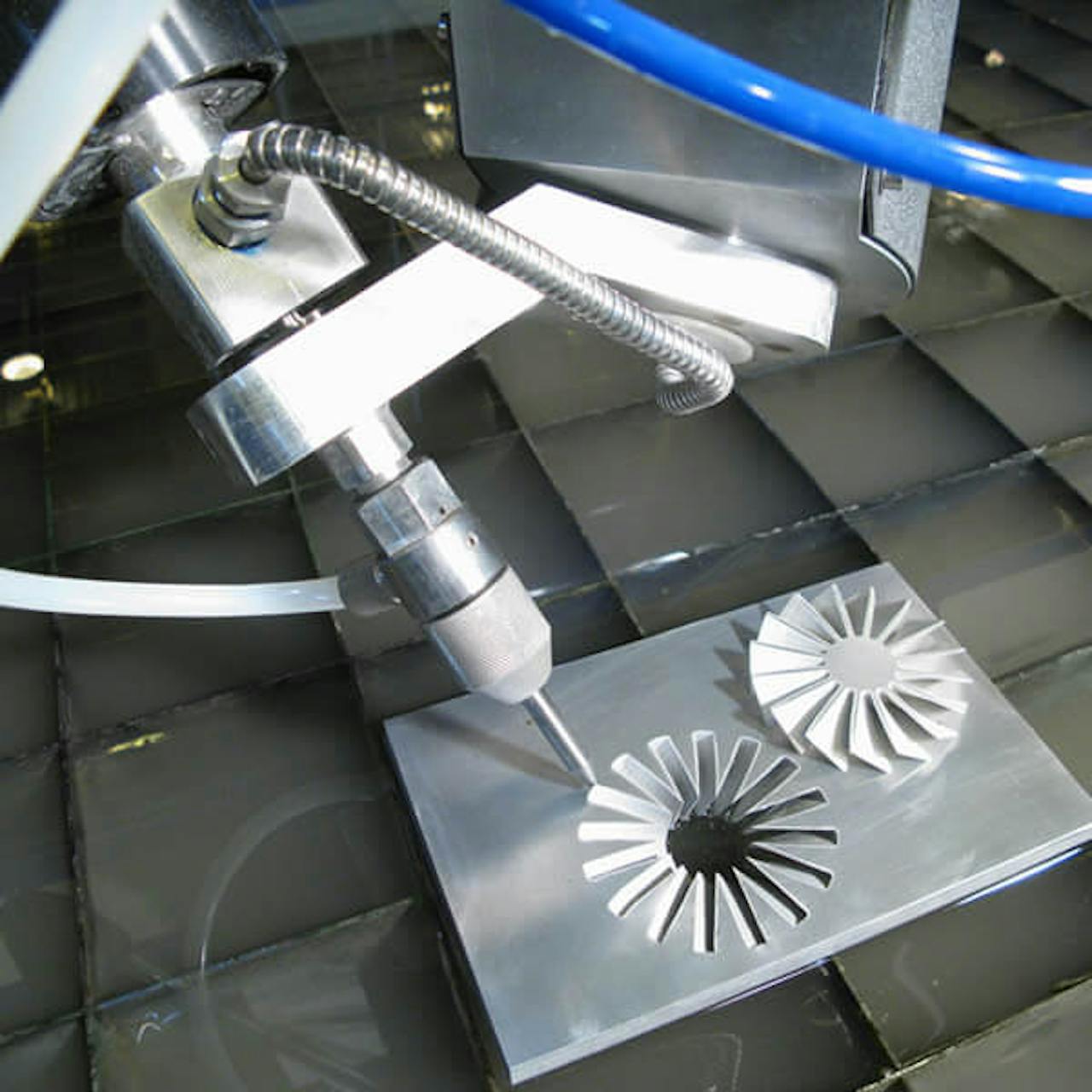

5 Axis WaterJet Cutting

The waterjet cutting process combines high-pressure technology and dynamic cutting heads to cut materials 2-4 times faster than traditional waterjet cutting methods.

Our Mach 4 system boasts the tightest tolerances possible within the waterjet cutting space, which lowers cycle times and ultimately saves you money.

Additionally, our Dynamic Waterjet XD technology allows us to cut materials in 3D, which enhances beveling capabilities up to 60 degrees. This process makes easy work of tricky cutting angles and ensures for versatility in the manufacturing process.

Why Use Waterjet Cutting?

Unlike laser cutting and traditional cutting methods, Waterjet cutting does not distort or alter the material's structure during cutting. Its 3D capabilities also allow for cutting a variety of complex shapes not achievable with other methods.

Furthermore, the waterjet's precise cutting method does not require additional secondary processes like sanding or grinding and produces no harmful chemical byproducts (unlike plasma cutting and laser cutting), saving time, money, and environmental costs.

Materials

MW works with a variety of industries—automotive, aerospace, industrial, agriculture, food and beverage, oil and gas, military, and more.

Our waterjet cutting service can cut materials up to 8 inches thick with outstanding edge quality and no heat-affected zone. It can cut materials of several different compositions, including the examples below.

Quality Standards & Certifications

At MW, we pride ourselves on creating quality products that meet or exceed industry standards. Not only do our facilities perform rigorous quality assurance testing to your specified ranges, but we also maintain several key certifications to ensure that only the best products are shipped to you.

What We Offer

Whatever your industry or desired materials, from tile and ceramics to rubber or plastics, our job shops can cut the materials you need to the specifications that you require. MW Components has the knowledge, the tools, and the capabilities to help you get the job done. Ready to get started? Request a free quote now.