Century Spring

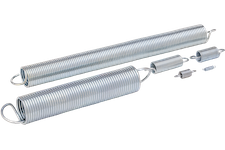

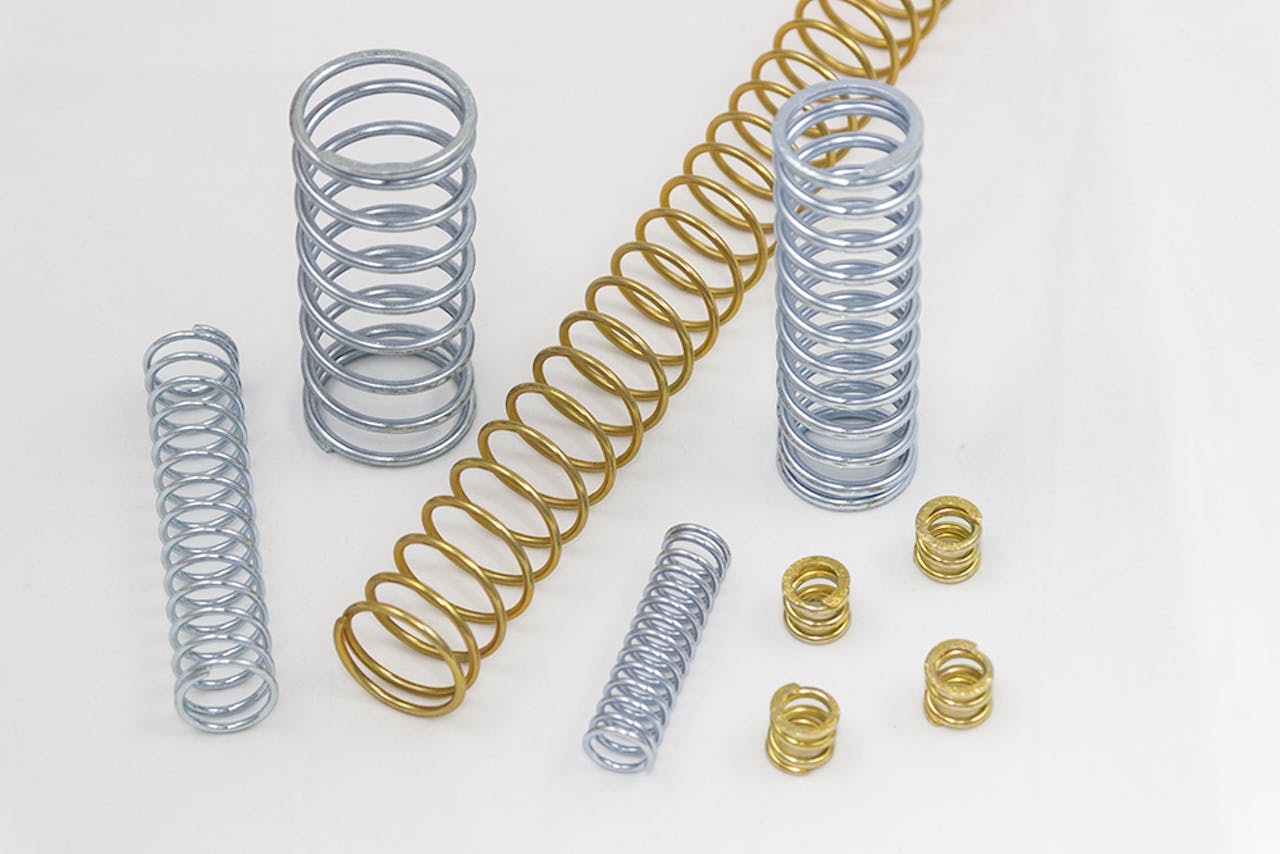

The World's Largest Selection of Stock Springs

Century Spring is a made-in-the-USA manufacturer of stock and custom springs. With over 40,000 designs and millions of parts in stock, Century can support nearly any springs needs, from compression and extension springs to die springs and stove handles. Visit Century's website to shop in-stock parts with same-day shipping, or request a quote for quick turn custom manufacturing.

Shop Century Products

Custom Spring Manufacturing

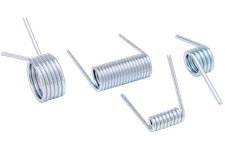

Custom Springs

Century Spring offers the latest technology and design assistance for customers who need custom springs or wireforms. Century's CNC machines can produce over 35,000 springs per hour and our advanced imaging and sorting systems are capable of performing 100% inspections on your parts, so you’ll get the quality you need. We turn around most custom spring quotes in just 1-2 business days. Production lead time is typically 2-4 weeks from the order date.

Contact us for design support or request a quote for pricing.

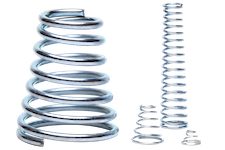

2-Week Delivery on 17-7SS Springs

Century Spring offers custom compression springs in Stainless Grade 17-7 PH ® . 17-7 stainless steel is a precipitation hardening stainless steel that provides exceptional benefits in a wide variety of applications, including aerospace and defense. Century Spring now stocks 17-7 stainless steel material, allowing us to provide rapid turnaround. Submit a purchase order for custom 17-7 compression springs and Century will deliver in two weeks or less.

View Century's 17-7 Brochure here or request a quote to get started.

““You make my job as a designer so easy. I just want to thank you! Love your CAD downloads, large stock, and reasonable prices for prototyping and low quantities.””

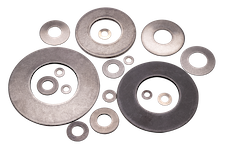

Springs for Any Industry

40,0000+ Designs In Stock for Aerospace, Medical, and More

Whether you need same-day shipping on a stock part or quick turn custom manufacturing with industry-specific quality certifications, Century Spring can help. We have over 8,000 medical-grade 316 stainless steel springs in stock that are ideal for healthcare applications, as well as 17-7 stainless steel, beryllium copper, music wire, phosphor bronze, and other materials.

Century also holds numerous quality certifications and upholds strict regulatory standards. From ISO9001 and AS9100D to material safety and conflict mineral standards, we do everything possible to ensure we're providing high-quality, ethical products.

Century Spring Catalog & Questions

Need a print catalog? Century Spring's catalog is free and available for all our customers. Just fill out the form on CenturySpring.com and tell us where to sent your copy.

Have questions? Email us at info@centuryspring.com or call us at 800.237.5225 if you have questions on our services, need design support for a custom product, or simply want to get in touch with an expert.